|

|

|||||||||||||||

![]()

|

|

|||

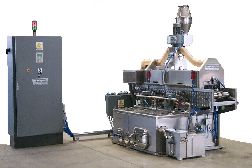

TUNNEL washers are designed for continuous cleaning of mechanical parts using water base detergents and are typical for single or multi-stages process with a high throughput. Parts can be processed singly or in batches. TUNNEL washers are commonly used in the production lines of the mechanical, automotive and aerospace industry either for interprocess or final cleaning. For their flexibility they are suitable to mass or limited production. |

|

||

Machines with small footprint and extremely compact have been developed to fit process lines in the automotive industry. For that, specific techniques have been developed: conveyors with specific characteristics to minimize drag out of liquids, drying systems with and without heating, compact systems for heating, ventilation and filtration. Using new technologies PASSAPONTI has also developed drying systems based on the air knife technique that can reach 70°C without heating elements or using compressed air but with very low consumption and noise below 70 dBA. TUNNEL washers are equipped with forced ventilation to capture vapours with very low energy consumption and usable with the mist eliminator RETEN-MIST®or the vapour condenser VAPOR-MIST®avoiding the cost of ducts to the external. TUNNEL washers are composed by a robust self contained, floor mounted structure with the conveyor, tanks, spray system and all the relevant equipment. The conveyor is driven by a gearmotor with torque limiter, adjustable speed and automatic controls and safety equipment. The spray system is composed by the pump and the spray headers with quick disconnect calibrated nozzles. Special care is dedicated to maintenance with easy access to all parts. Before entering the tank the wash liquid passes through a gravity-fed filter easily accessible for cleaning. To reduce drag out of the liquids, process stages are separated by vestibules with curtains. Tanks with heating are insulated with mineral wool and equipped with a filter, drain out valve, marine type clean out door, overweir, low level cut out, and additional facilities such as the automatic oil separator OILNET®, bag or cartridge filters and more. |

|||